METRIC THREADS: THE MEANING OF THE METRIC NUMBERS

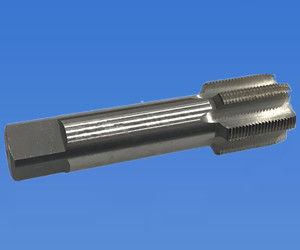

If you check the metric thread tap, you will see some letters and numbers there, but what do the letters and numbers mean?

Let's begin with the M10 part. The massive M means it is a metric thread tap. The 10 is the nominal outside diameter of the thread, in tech-speak the good diameter. Then it would be 10mm.

If you take a look at it, you could see that it is a little bit under 10mm. It is normal for the outside diameter of a thread to be a little smaller more than its certain worth.

Calculating the main diameter of a thread.

M10 threads with different thread pitches

1.5 is the thread pitch - the spacing between one sharp little bit of a thread and the next one along, it's miles 1.5mm.

The braking device on motorcycles is often a filed where finer thread pitches are used. If the bolt doesn't size it, test it properly; maybe you're using the proper pitch bolt.

One final essential component to know is the interior diameter of a thread. For M10 x 1.50, this is around 8.50mm. This diameter decides the form of tapping drill used.

Scaling the internal (minor) dia. Of a thread

Cutting threads making use of taps and dies

To slice an interior thread, you have to set taps of the proper thread size and pitch. Generally, metric thread taps are given as a fixed of three, designed taper, second and bottom. You'll also want a tap wrench to show the tap.

Thread Repair Kits

In a few stages, you may go through stripping a thread (advertising a threaded hole so that you can no longer successfully screw a bolt into it). There are many techniques to repair this, the one you pick out will rely entirely on what's the most competent for the job, or what devices you have to hand. The easiest strategies are likely to drill the hole out and re-tap it to take a large thread size, if possible. Next, you could get the hole welded up, then re-drill and tap as needed. Thirdly, you could attempt solving the thread making use of a thread repair kit.

There are two varieties of repair kit; those that have injects that appear to be small springs and those that have stable threaded inserts. They are generally called Helicoils or Timeserts, respectively. Fortunately, there are a few affordable(look-alike) kits accessible, but are they any good?

Fixing Stripped Threads

The parts of a Helicoil kit are the inserts, a unique tal, and the installer too. It would help if you offered the drill bit for maximum kits.

In this instance, a tap isn't always going to reduce it, the threads are wasted, and while you might be capable of getting a little bit with a tap, it won’t last. HeliCoil insert or Timeserts can be used for the repair. You can use different thread repair insert and tanged is the common. These inserts have a diamond-fashioned cross-segment with 60-diploma threads on the inside and specially designed threads at the outer ring, which grips the partitions of the hole.

Contact:

Chenchuan Tools Co.,LTD

Chenbei Industry Zone,

Longgang Road,

Huangshi,Hubei

China,435202

Tel: 0714-7321211

Fax: 0714-7321210

Comments

Post a Comment