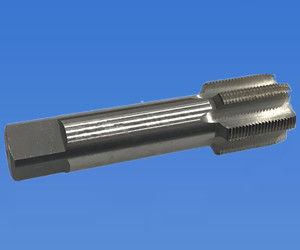

The Best Practices When Using UN Thread Taps And Thread Gauges

Have you been lately experiencing constant issues with your UNEF thread gages and thread taps? Are you forced to replace them more frequently than ever? Does this increase your overhead costs month after month reducing your profits? If yes, then the chances are that you are not following the best practices when using your thread gauges and thread taps. Let us explore some of the best factors to keep in mind when it comes to thread gauge and thread tap usage best practices.

To start with you must get the right tool for the right job. If you are purchasing your thread taps you cannot pick any random thread taps. You should first do your research trying to find the most suitable thread tap for the material at hand. Some materials are brittle and they will have brittle particle residue when tapping while other materials are more tensile and as you tap thread, they will form thin or fine stringy peels. You must therefore take such factors into account when picking the thread taps. If you use the wrong type of thread taps then you will not be able to get the results you want and you are also susceptible to frequent damages not only of the thread taps but also damages to the components that you are manufacturing.

When you are using your UN Thread Taps make sure only skilled employees are assigned to handle the tapping process. Like right tool for the right job, it is important that you have the right people for the right job. Those who are using the thread taps must be given adequate training and should have clear set of instructions on thread tap maintenance and care.

Simple protocols such as pre-use and post-use cleaning should be done. The tools must be stored in their respective protective sheaths. You must not mix up the tool and its sheath because when you want to quickly access the right tool, you will not be able to find them fast. In the rush, you could even pick the wrong tool and it will damage your tool and your component that is being manufactured.

All that it takes is sticking to very simple basic rules when using your thread gauges and thread taps. This will go a long way in protecting your tools and getting the best life out of them.

To start with you must get the right tool for the right job. If you are purchasing your thread taps you cannot pick any random thread taps. You should first do your research trying to find the most suitable thread tap for the material at hand. Some materials are brittle and they will have brittle particle residue when tapping while other materials are more tensile and as you tap thread, they will form thin or fine stringy peels. You must therefore take such factors into account when picking the thread taps. If you use the wrong type of thread taps then you will not be able to get the results you want and you are also susceptible to frequent damages not only of the thread taps but also damages to the components that you are manufacturing.

When you are using your UN Thread Taps make sure only skilled employees are assigned to handle the tapping process. Like right tool for the right job, it is important that you have the right people for the right job. Those who are using the thread taps must be given adequate training and should have clear set of instructions on thread tap maintenance and care.

Simple protocols such as pre-use and post-use cleaning should be done. The tools must be stored in their respective protective sheaths. You must not mix up the tool and its sheath because when you want to quickly access the right tool, you will not be able to find them fast. In the rush, you could even pick the wrong tool and it will damage your tool and your component that is being manufactured.

All that it takes is sticking to very simple basic rules when using your thread gauges and thread taps. This will go a long way in protecting your tools and getting the best life out of them.

Comments

Post a Comment