What Should You Know About Metric Thread Gauges?

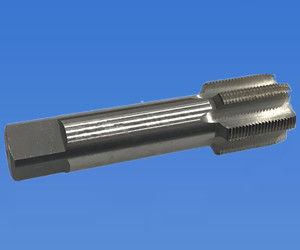

Metric thread gauges are essential tools used in various industries to ensure the accuracy and interchangeability of threaded components. These are precision instruments used to measure, inspect, and calibrate metric screw threads.

They consist of a threaded gauge and a reference gauge that help determine if a threaded component meets the specified standards. Metric thread gauges are manufactured with high precision to ensure accurate measurements and promote compatibility between different threaded parts.

Types of Metric Thread Gauges

• Thread Plug Gauges

Thread plug gauges are used to measure the internal threads of nuts or tapped holes. They have a threaded end that must fit smoothly into the thread being measured. If the gauge does not fit or fits too loosely, it indicates non-conformance to the specified thread standards.

• Thread Ring Gauges

Thread ring gauges are employed to inspect external threads of screws or bolts. These gauges have a threaded ring that should fit snugly over the tested thread. If the ring gauge does not fit or fits too tightly, it indicates a non-conforming thread.

Applications of Metric Thread Gauges

• Manufacturing and Engineering

Thread gauges are used during the production of threaded components, ensuring compliance with precise specifications, and facilitating proper assembly and fit.

• Automotive Industry

Metric thread gauges are vital for verifying the accuracy of threaded parts in automotive manufacturing, such as engine components, fasteners, and suspension systems.

Importance of Proper Usage

• Calibration

Regular calibration of UN thread gauges is crucial to ensure their accuracy. Gauges should be calibrated by accredited calibration laboratories or using a traceable reference standard.

• Correct Handling

Thread gauges should be handled with care to prevent damage to their delicate threads. They should be stored in protective cases when not in use and kept away from contaminants to maintain their precision.

• Regular Maintenance

Regular cleaning and maintenance of thread gauges are necessary to remove dirt, debris, and corrosion. Proper lubrication should be applied to ensure smooth thread engagement and prevent wear.

• Training and Expertise

Individuals using metric thread gauges should receive adequate training and possess a solid understanding of the relevant standards. This helps minimize errors and ensures accurate measurements.

Conclusion

Metric thread gauges play a vital role in guaranteeing the precision and interchangeability of threaded components across various industries. Understanding the types, applications, and proper usage of these gauges is crucial for maintaining quality standards and ensuring reliable connections. By adhering to best practices, including regular calibration and maintenance, industries can benefit from the accuracy and efficiency that metric thread gauges provide.

Comments

Post a Comment