Sourcing Custom Thread Gauges And Thread Globally - Expanding Options for Specialized Needs

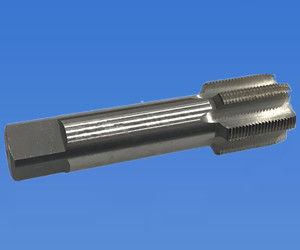

In the realm of manufacturing, precision tools play a vital role in ensuring quality and accuracy. ACME thread gauges and thread taps are essential components, guaranteeing the integrity of threaded products across diverse manufacturing industries. However, when it comes to addressing specific and unique requirements, the quest for precision often leads to the demand for custom tools. These customized tools cater to specialized needs, offering a level of precision that standard tools may not achieve.

A key incentive for acquiring custom thread gauges and thread taps is the quest for precision tailored to distinct applications. Manufacturing procedures exhibit notable variations, and off-the-shelf tools might not consistently meet the demanded precision. Custom thread gauges and ACME thread taps undergo meticulous design and craftsmanship to align with precise specifications, guaranteeing that each threaded element complies with the industry's stringent quality and performance benchmarks.

Custom tools truly shine when unique requirements come into play. Whether it is a non-standard thread profile, an unconventional material, or a specialized application, custom thread gauges and thread taps can be engineered to address these distinctive needs. This versatility proves invaluable in industries where innovation and uniqueness are paramount, allowing manufacturers to push the boundaries of what is possible.

Custom thread gauges and thread taps are designed with efficiency as a central focus. They are tailored to perform specific tasks with maximum efficiency, reducing waste and optimizing production processes. This efficiency can lead to significant time and cost savings over the long term, making custom tools a wise investment for businesses with specialized needs.

One significant advantage of opting for custom thread gauges and thread taps is the level of quality assurance it affords. Manufacturers can work closely with suppliers to define quality standards, conduct stringent testing, and ensure that the custom tools not only meet but often exceed industry requirements. This level of oversight and control is often challenging to achieve with standard tools.

Today's globalized manufacturing landscape has opened a realm of possibilities when it comes to procuring custom thread gauges and thread taps. Recent advancements in communication and logistics have paved the way for businesses to tap into a worldwide network of suppliers and manufacturers possessing the precise expertise and capabilities necessary to fulfil their distinct tool requirements. This expansive global reach grants access to specialized knowledge and cutting-edge technologies that might not be as easily accessible within local markets.

Comments

Post a Comment