Thread Gauges And Thread Taps Cost Comparison - Crucial Factors To Consider

When it comes to procuring Metric thread gauges and thread taps, businesses are faced with a decision that goes beyond the apparent price tags. The cost comparison involves a nuanced evaluation of various factors that collectively impact the overall value and efficiency of these essential tools. One crucial aspect is the material used in the manufacturing of thread gauges and taps. The choice of material significantly influences the durability, performance, and longevity of these tools. While certain materials may come at a higher initial cost, their extended lifespan and resistance to wear and tear can result in long-term cost savings.

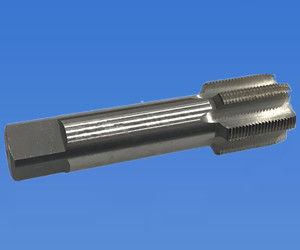

Precision is paramount in industries utilizing thread gauges and ACME thread taps, and the accuracy of these tools is closely tied to the manufacturing processes employed. The level of precision achieved during production can affect the overall quality of the threads and, consequently, the efficiency of the entire manufacturing process. Therefore, it's essential to consider the manufacturing standards and processes of potential suppliers when comparing costs. Investing in thread gauges and taps manufactured with high precision not only ensures accurate results but can also contribute to the longevity of the tools.

The cost of maintenance and calibration is another critical factor that often gets overlooked in the initial cost comparison. Regular maintenance and calibration are essential to uphold the accuracy and functionality of thread gauges and taps over time. Suppliers offering tools with features that facilitate easier maintenance and calibration may incur additional upfront costs, but these can translate into long-term savings by reducing downtime and ensuring consistent performance.

Additionally, the manufacturer's reputation is a key factor in the cost assessment. A manufacturer known for consistently delivering high-quality tools is expected to provide products that adhere to strict industry standards. Although these manufacturers may have slightly elevated initial costs, the dependability and durability of their thread gauges and taps can lead to a more cost-effective outcome. Opting for a reputable manufacturer helps reduce the likelihood of premature tool failure, thereby ensuring a manufacturing process that is both reliable and efficient.

The variety of thread gauges and taps needed for particular applications is an additional aspect impacting costs. If you are looking for custom-made thread gauges and thread taps then it would have a direct impact on the costing as opposed to the standard sizes which are mass produced.

Comments

Post a Comment